-

-

-

Packing

Sea freight standard packing, plywood box.

GSH Series High Temperature Yarn Dyeing Equipment | Professional Hank Yarn Dyeing Solution

Product Overview: Multi-Functional Integrated Dyeing System

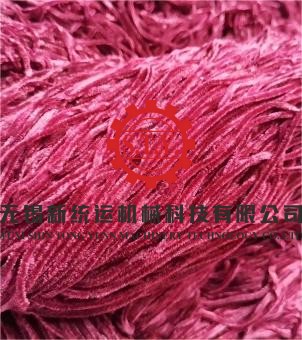

GSH Series high temperature polyester hank yarn dyeing machine is specifically designed for polyester yarn, chenille, embroidery thread, shoelaces, nylon hank yarn, and similar materials. The high temperature dyeing equipment integrates bleaching, refining, dyeing, washing and pre/post-treatment function, meeting modern textile manufacturers' demands for high efficiency & low energy consumption.

Product Characteristics

- Anti-Cavitation Reinforced Pump System: Maintains powerful spray capability even at high temperatures

- Patented Weir-Flow Spray Pipe: Combining spray/yarn turn/position in one unit

- Indirect Heating System: Ensures temperature uniformity (±0.5°C) under high pressure

- Ultra-Low Dyeing Loss: Yarn entanglement rate <0.3%, without stains and piling.

Technical Parameters

Key Performance Indicator of high temperature yarn dyeing equipment

| Material |

Polyester/Nylon/Embroidery Thread (hank form) |

| Design Max Working Temp. |

140°C (284°F) |

| Design Max Working Pressure |

0.4MPa (58 psi) |

Standard Features of Polyester Hank Yarn Dyeing Machine

- Full Stainless Steel Contact Parts: high quality corrosion resistance stainless steel-dye vat/spray pipes, etc..

- 5-in-1 Dyestuff Tank: Integrated mixing/heating/water inlet/reflow/add dyestuff

- High-Performance Mixed-Flow Pump: stainless steel

- Automatic Water Level Indicator: Digital display (±1% accuracy)

- Cleaning Tool: hank yarn load in and out hook/cleaning spray pipe brush

Four Advantages

- 40% Improved Dyeing Uniformity: Patented weir-flow spray tube eliminates uneven dyeing

- Significant Energy Savings: Heat recovery system + indirect heating reduces energy consumption by 25-30% vs competitors

- Minimal Maintenance Costs: Modular design reduces key component replacement time by 70%

- Smart Control Options: Available auto-dosing system can be set in dyeing controller

Optional Upgrades

- Customizable configurations: Automation: Semi-auto/full-auto control system

- Precision Dosing: analog quantity

- Spray Pipe Lengths: 600/1500/1800/2000mm options

- Quick-Open System: Hydraulic-assisted lid

Textile Machine Manufacturer in China Share Custom Solution

Contact Us Now!

1-on-1 Consultation with Engineers

1-on-1 Consultation with Engineers

Free Technical Data

Free Technical Data

Schedule Factory Tour

Schedule Factory Tour

For larger capacity, see our 600kg Yarn Dyeing Machine

GSH HIGH TEMPERATURE HANK YARN DYEING MACHINE

| MODEL |

CAPACITY(KG) |

NO. OF SPRAY PIPE |

MAIN POWER(KW) |

| GSH-1-60 |

5 |

1 |

1.1 |

| GSH-2-60 |

10 |

2 |

2.2 |

| GSH-2-150 |

20 |

2 |

3 |

| GSH-3-150 |

30 |

3 |

4 |

| GSH-4-150 |

40 |

4 |

5.5 |

| GSH-6-200 |

120 |

6 |

7.5 |

| GSH-6X2-200 |

240 |

12 |

15 |

| GSH-6X4-200 |

480 |

24 |

22 |

| GSH-6X6-200 |

720 |

36 |

37 |

| GSH-6X8-200 |

960 |

48 |

45 |

Last Updated: 2024-12

TEXTILE MACHINE MANUFACTURE IN CHINA - WUXI SHIN TONG YUNN MACHINERY TECHNOLOGY CO., LTD

IPv6 network supported

IPv6 network supported